Retpoŝta formata eraro

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

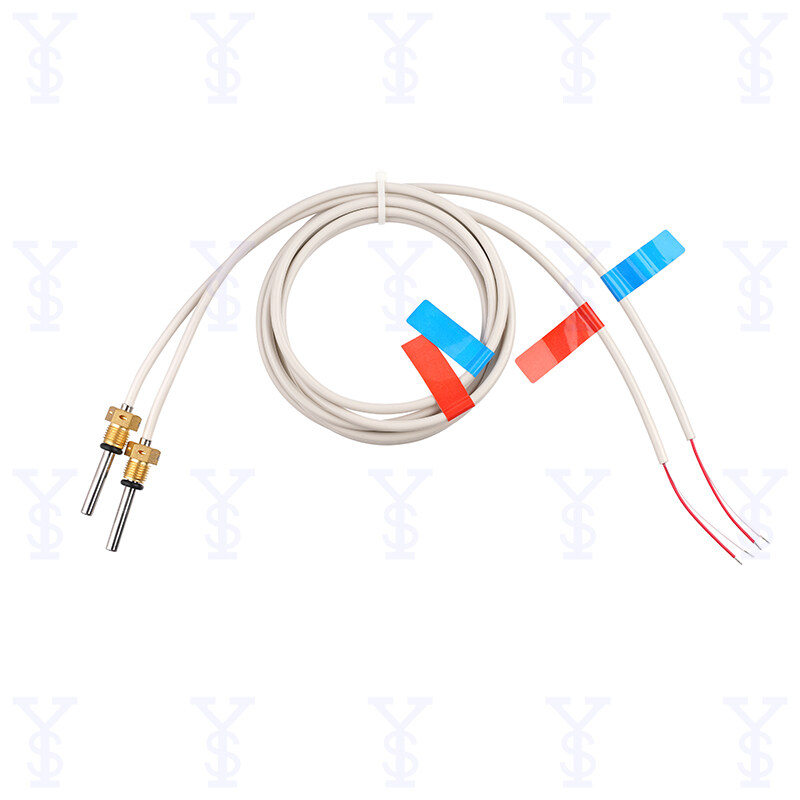

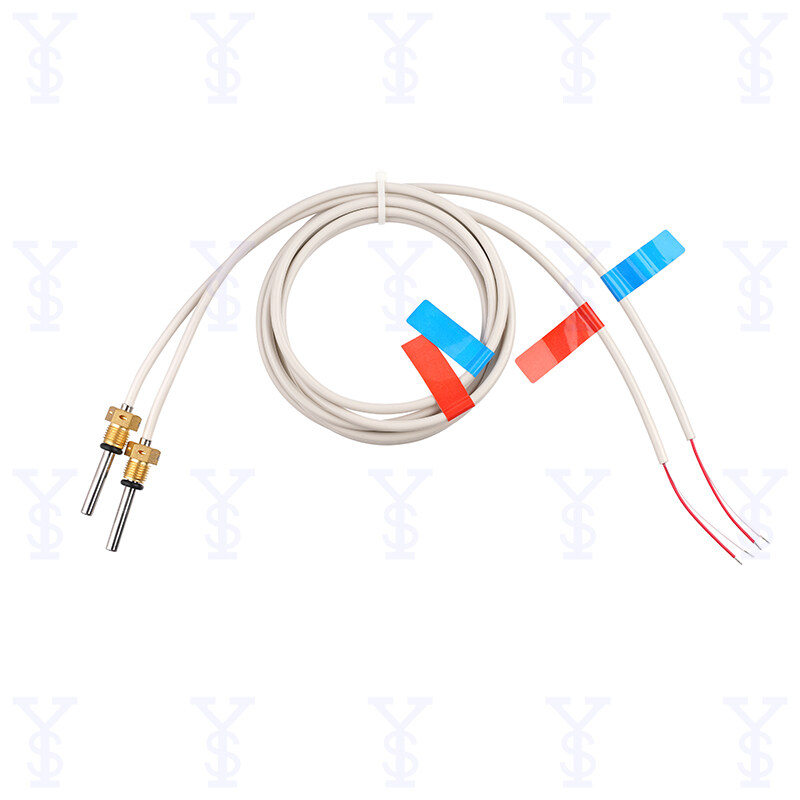

Comprehensive Guide to 4 Wire RTD Temperature Sensors

In the realm of temperature measurement technology, the 4 wire RTD temperature sensor stands out as a robust and accurate tool. This blog post aims to explore the intricacies of 4 wire RTD sensors, including their principles, applications, advantages, and more. Whether you are an engineer, researcher, or enthusiast, this guide will provide you with valuable insights into the world of RTD sensors.

Understanding 4 Wire RTD Temperature Sensors

A 4 wire RTD (Resistance Temperature Detector) sensor is a type of temperature sensor that utilizes the change in electrical resistance of a metal wire to measure temperature. It is known for its high accuracy and stability over a wide temperature range, making it suitable for various industrial and scientific applications.

How 4 Wire RTD Sensors Work

4 wire RTD sensors operate on the principle that the electrical resistance of certain metals, such as platinum (Pt), changes predictably with temperature. They are called "4 wire" because they use four wires to connect the sensor to the measurement circuit: two wires for supplying excitation current and two wires for measuring the voltage drop across the RTD element.

Measurement Principle

1. Excitation Current: A known current is passed through the RTD sensor via the excitation wires.

2. Voltage Measurement: The voltage drop across the RTD sensor is measured using the measurement wires.

3. Temperature Calculation: The measured voltage drop is converted into temperature using the known characteristics of the RTD sensor's resistance vs. temperature curve.

Applications of 4 Wire RTD Temperatures Sensors

4 wire RTD sensors find applications in various industries where precise temperature measurement is critical. Here are some common applications:

Industrial Processes

In industrial processes such as manufacturing and chemical processing, 4 wire RTD sensors are used for temperature monitoring and control. Their high accuracy and stability ensure consistent process control and product quality.

HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems utilize 4 wire RTD sensors to monitor air and water temperatures. Accurate temperature measurement helps optimize energy efficiency and maintain comfort levels.

Aerospace and Defense

In aerospace and defense applications, where temperature extremes are common, 4 wire RTD sensors provide reliable temperature monitoring for critical systems and equipment.

Laboratory Research

In scientific research and laboratory environments, 4 wire RTD sensors are used in experiments and studies where precise temperature control and measurement are essential.

Automotive Industry

Automotive testing and development rely on 4 wire RTD sensors to monitor temperatures in engines, exhaust systems, and cooling systems. Accurate temperature data is crucial for engine performance and emissions control.

Advantages of 4 Wire RTD Temperature Sensors

4 wire RTD sensors offer several advantages that contribute to their widespread use:

High Accuracy

4 wire RTD sensors provide highly accurate temperature measurements, typically with an accuracy of ±0.1°C or better. This precision is critical in applications where temperature control directly impacts product quality or process efficiency.

Stability

Due to their stable resistance characteristics, 4 wire RTD sensors offer excellent long-term stability. They maintain their calibration over extended periods, reducing the need for frequent recalibration.

Wide Temperature Range

4 wire RTD sensors can measure temperatures from -200°C to over 600°C, depending on the type of RTD element used (usually Pt100 or Pt1000). This versatility makes them suitable for a wide range of industrial and scientific applications.

Low Drift

The low drift of 4 wire RTD sensors ensures that temperature readings remain accurate even in demanding environments or over prolonged use.

Compatibility

4 wire RTD sensors are compatible with most measurement and control systems, making them easy to integrate into existing setups without extensive modifications.

Comparison with LPTC Temperature Sensors

While 4 wire RTD sensors excel in accuracy and stability, LPTC (Low Power Temperature Coefficient) sensors are valued for their low power consumption and small size. LPTC sensors are often used in battery-powered devices or applications where space is limited. Each type of sensor has its strengths, and the choice depends on the specific requirements of the application.

Choosing the Right 4 Wire RTD Temperature Sensor

Selecting the right 4 wire RTD sensor involves considering several factors:

Temperature Range

Ensure that the sensor's temperature range matches the requirements of your application. Different RTD elements are available for different temperature ranges.

Accuracy Requirements

Consider the level of accuracy needed for your application. Higher accuracy sensors may be required for critical processes or research applications.

Response Time

Evaluate the sensor's response time, especially if rapid temperature changes need to be monitored.

Environmental Conditions

Choose a sensor that can withstand the environmental conditions (e.g., humidity, vibration, corrosive substances) present in your application environment.

Calibration and Maintenance

Plan for regular calibration and maintenance to ensure continued accuracy and reliability of temperature measurements.

Installation and Calibration Tips

Proper installation and calibration are essential for accurate temperature measurement with 4 wire RTD sensors:

Installation

- Placement: Position the sensor where it can accurately measure the temperature of the medium being monitored.

- Wiring: Connect the sensor properly according to the manufacturer's instructions to minimize electrical noise and interference.

- Protection: Protect the sensor from physical damage and exposure to harsh environmental conditions.

Calibration

- Calibration Standards: Use calibrated reference standards to verify the accuracy of temperature readings.

- Calibration Intervals: Establish a regular calibration schedule based on the sensor manufacturer's recommendations and your application requirements.

Future Trends in 4 Wire RTD Sensor Technology

The field of 4 wire RTD sensors continues to evolve with advancements in materials, manufacturing techniques, and sensor technology. Here are some future trends to watch:

Miniaturization and Integration

Advancements in miniaturization will enable smaller and more integrated 4 wire RTD sensors, expanding their use in compact and portable devices.

Wireless Connectivity

Integration with wireless communication technologies will enable real-time monitoring and remote control of temperature data, enhancing efficiency and convenience.

Enhanced Durability

Improvements in sensor durability and robustness will extend the lifespan of 4 wire RTD sensors in challenging industrial environments.

Smart Sensor Capabilities

Integration with smart sensor technologies and IoT platforms will enable advanced analytics and predictive maintenance capabilities based on temperature data.

Conclusion

In conclusion, the 4 wire RTD temperature sensor is a cornerstone of modern temperature measurement technology, offering unparalleled accuracy, stability, and versatility across various industries and applications. Whether used in industrial processes, scientific research, automotive testing, or HVAC systems, 4 wire RTD sensors provide reliable temperature data critical for optimizing performance, ensuring product quality, and maintaining safety standards.

Understanding the principles, applications, advantages, and selection criteria of 4 wire RTD sensors is essential for making informed decisions in temperature sensing technology. As technology advances and new applications emerge, the role of 4 wire RTD sensors will continue to expand, driving innovation and efficiency in temperature measurement and control systems worldwide.

If you are considering integrating 4 wire RTD sensors into your next project or upgrading existing temperature monitoring systems, the insights provided in this guide will serve as a valuable resource. Embrace the precision and reliability of 4 wire RTD sensors to elevate your temperature measurement capabilities and unlock new possibilities in your applications.